Since 1972, KCA has fabricated portable or modular carbon adsorption, carbon desorption, carbon stripping and Merrill-Crowe plants. KCA’s plants have earned an outstanding reputation for quality, simplicity, ease of start up and fail-safe operation. Modular plants can be constructed for gold operations treating up to 4,000 tonnes of ore per day. Above that size, plants are built on-site.

KCA’s modular plants allow for rapid installation at remote sites, are easily movable, and have a high resale value.

KCA offers four different modular ADR plant models:

KCA also manufactures modular Merrill-Crowe recovery plants for operations processing up to 10,000 tonnes of gold/silver ore per day ranging from 20 to 500 m³/hr:

A list of projects for which KCA has fabricated modular plants is presented below.

| Operation | Location | Type | Size (m³/hr) |

|---|---|---|---|

| Afema | Ivory Coast | Carbon Adsorption & Ethanol Strip | 50 |

| Afema II | Ivory Coast | Carbon Adsorption & Ethanol Strip | 100 |

| Afema II | Ivory Coast | Carbon Regeneration | 25 kg/hr |

| Al Hajal | Saudi Arabia | Carbon Adsorption & Ethanol Strip | 15 |

| Ashanti | Ghana | Carbon Adsorption & Ethanol Strip | 125 |

| Aurex | Peru | Merrill-Crowe | 30 |

| Aurora | United States | Carbon Adsorption & Ethanol Strip | 50 |

| Bolnisi | Georgia, CIS | Carbon Regeneration | 25 kg/hr |

| Bolnisi | Georgia, CIS | Carbon Adsorption & Ethanol Strip | 50 |

| Cetco Mill | Russia | Vacuum/Deaeration Circuit | 250 |

| Choquelimpie | Chile | Carbon Adsorption & Ethanol Strip | 225 |

| Cripple Creek | United States | Carbon Adsorption & Ethanol Strip | 55 |

| El Cubo Phase I | Mexico | Merrill-Crowe | 120 |

| El Cubo Phase II | Mexico | Merrill-Crowe | 121 |

| El Magistral | Mexico | Carbon Adsorption | 70 |

| El Plomo | United States | Carbon Adsorption & Ethanol Strip | 15 |

| Essakan | Burkina Faso | Carbon Adsorption & Ethanol Strip | 30 |

| Fazenda Nova | Brazil | Carbon Adsorption | 450 |

| Getchell | United States | Carbon Adsorption & Ethanol Strip | 45 |

| Gilbert | United States | Carbon Adsorption & Ethanol Strip | 50 |

| Gordex | New Brunswick | Carbon Adsorption & Ethanol Strip | 30 |

| Hassai | Sudan | Carbon Adsorption & Ethanol Strip | 20 |

| Hassai | Sudan | Carbon Regeneration | 25 kg/hr |

| Hayden Hill | United States | Carbon Adsorption | 45 |

| Ivrindi | Turkey | Carbon Adsorption | 3200 |

| La Sorpresa | Mexico | Merrill-Crowe | 65 |

| Little Bald Mtn. | United States | Carbon Adsorption & Ethanol Strip | 20 |

| Magistral | Mexico | Carbon Adsorption & Ethanol Strip | 70 |

| Marvel Loch | Australia | Carbon Adsorption & Ethanol Strip | 35 |

| Mascota | Mexico | Carbon Adsorption | 340 |

| Newmont Tailings | United States | Carbon Adsorption | 22 |

| San Antonio | Mexico | Merrill-Crowe | 70 |

| San Martin | Mexico | Merrill-Crowe | 70 |

| Santiago de Chuco | Peru | Carbon Adsorption & Zadra Strip | 20 |

| Santiago de Chuco | Peru | Carbon Regeneration | 42 kg/hr |

| Scott-European | Russia | Carbon Adsorption & Zadra Strip | 20 |

| Seligdar | Siberia | Carbon Adsorption & Zadra Strip | 50 |

| SSATE | Saudi Arabia | Carbon Adsorption & Ethanol Strip | 125 |

| Sterling | United States | Carbon Adsorption & Zadra Strip | 35 |

| Sterling II | United States | Carbon Adsorption & Ethanol Strip | 200 |

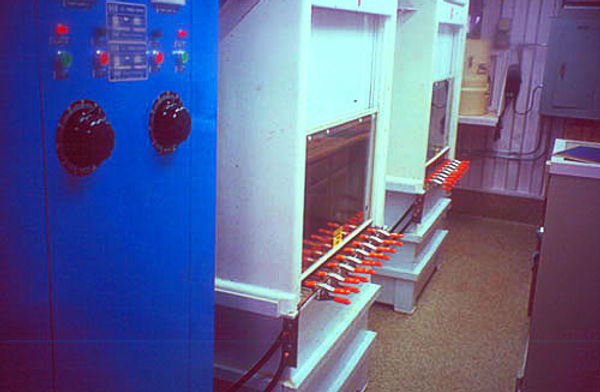

The Al Hajal plant (also used at the Hamdah project) in Saudi Arabia is a complete plant for production of dore gold bars, mounted in a 6-meter (20-foot) container. The smelting furnace can be seen on the concrete slab on the right side of the photo. This size plant is ideal for heap leach tests or very high grade small operations (producing up to 400 tonnes of ore per day).

Sansu plant Shipping out of Reno, NV

Outside of Sansu Plant

Sansu Electrowinning Cell Room

Sansu Adsorption Plant

This seven million tonne gold heap leach is located at an altitude of 4600 meters (15,000 feet) in northern Chile. Through its associated company, Decommissioning Services LLC, KCA provided engineering, procurement and construction management (EPCM), and then subsequently entered into a 2-year contract to provide complete project operations management services.

The heap was an accumulation of ore from an on-off heap leach formerly operated by a large international mining corporation, Billiton. Based on an evaluation of exploration drillholes into the heap, KCA was able to show that washing would mitigate an environmental problem (high residual cyanide) and recover significant amounts of gold and silver. Under contract to the client, KCA designed and installed a stabilizing butress, a recovery plant, and a complete heap piping system. During three years of “washing”, precious metals production exceeded 30,000 ounces of gold, essentially in agreement with the projection made by KCA at the start of the project. The client realized an operating profit on this environmental cleanup project.

Getchell Plant

The Getchell, Nevada, Carbon ADR plant consists of a five-stage vertical tower adsorption column. Desorption and electrowinning take place inside the trailer. KCA has built several tower column plants, which offer portability and compact size.

The ore treated in this 1200 ton per day heap leach was unique in that it was high in oxidizing sulfides, including very reactive arsenic sulfides (orpiment and realgar). Solution exiting the heap was colored deep blue with iron ferrocyanide – a classic indicator of oxygen deficiency. Nevertheless, gold recovery was good, and by controlling cyanide addition rates the consumption of cyanide was maintained within economic limits.

KCA provided the lab testing, design, engineering, and construction management of the heap leach and recovery systems. KCA supplied the agglomeration drum and conveying and stacking systems, and a 180 gallon per minute five-stage tower column plant for carbon adsorption. In 1988, this plant was repurchased by KCA and re-installed at the Atlas Gold Bar mine.

KCA conducted laboratory investigations on ore samples from the deposit, provided conceptual design of heap leach pads and ponds, and developed the operating philosophy. KCA also provided the design, construction, and start-up of a complete gold adsorption-desorption-recovery plant rated at a production capacity of 300 tons per day. Direct capital and operating costs were repaid within the first season.

The Little Bald Mountain plant is typical of small ADR plants (Adsorption-Desorption-Recovery Plants) built by KCA.

All operations needed for recovery of gold and silver from solution onto activated carbon, desorption, and electrowinning of metal bullion, are included in a 40-ft (12 meter) trailer or shipping container.